A few weeks ago I had to take a couple of days off from still trying to catch up with some Christmas back orders. Feels like it doesn’t matter how soon I start preparing for the holidays it’s never early enough. This time, it was middle of October when I started cleaning barrels tops and milling runners for our very popular whiskey barrel head clocks. Since they are a small home decor product and because of their massive market, they have become our number one holiday seller. Every time I think we have the right amount ready for the end of the year rush, a few days into December the realization hits me. We are going to need at least 25% more clocks ready to ship by next week or we may fall short and have to refund customers. Losing money and more frustratingly disappoint any holiday shoppers isn’t my style.

Long story short, with a few additional hours and couple extra weekends of work, everyone received their holiday gifts safely and on time. The only back orders we had are for buyers who purchased big furniture. Needless to say we did discussed it with them that during the holidays most large items will have to ship after Christmas. Lucky for us our furniture customers totally understand this and are more than happy to wait. So with only a few sets of barstools left on the back order list, it was time to go re-up on barrels.

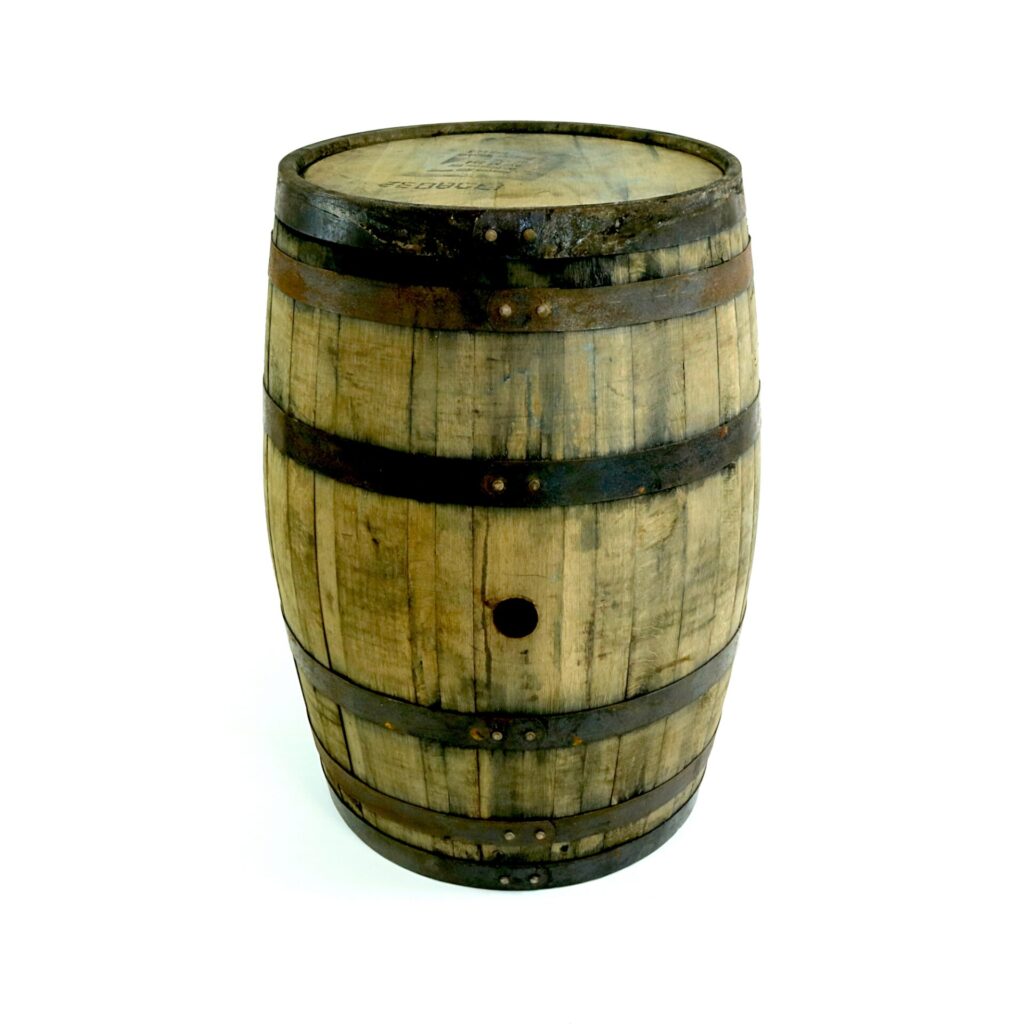

When it’s time to re-stock barrels I never wait for them to get low. I must feel secure with our inventory because sometimes you do have to search for them which requires lots of calls and emails. After all, wine and whiskey barrels aren’t usually sold down at every nursery or hardware store. Plus if you ever see some, the price tag on them is usually few hundred percent more than what their whole price really is. This is because of their logistics. When a barrel is still moist and solid it can weight up to 125 lbs. They are 34″ tall and about 26″ at their widest point. Shipping one with FedEx Ground can cost up to $250. While freight will be cheaper, the quantity of a full truck load can lag. This is because everyone will ship them only on pallets for easy mobility.

New Batch of Whiskey Barrels

If you want to fill a whole semi from top to bottom you will have to do it yourself. This is definitely possible because carriers usually allow a 2 hour load time. But if you have to drive far or fly to their locations, then it might just be just simpler to rent a big box truck and do it yourself. This is what we do. Sure the gas price and our time can add up but, I like to have peace of mind that we are actually getting the best material and the maximum amount as possible. Loading a truck is hard and dirty work. Hopefully someone has thought you how to lift with your legs before setting off on this strong man exercise. I have moved well over 10,000 barrels and I did develop a good lifting technique. It’s all about quick swift motions and letting the barrel rest on the other barrels as you put them on one another.

Rolling them on the ground should be a no brainer. You can roll them horizontally or upright while slightly on their edge. If you mastered this skill be sure you do it only on floors that don’t matter if they get damaged. The metal bands will most likely dig into the surface. I have seen quite a few hardwood and even concrete floors get ruined this way. The shear weight of the barrel and the metal corner will become like a knife. Don’t worry, I too have accidentally sliced an extension cord like rolling them like this.

The types of barrels we most often get are bourbon whiskey barrel. The distilleries brands will often indued the following: Jim Beam, Buffalo Trace, Maker’s Mark, Wild Turkey, Four Roses, Barton 1792 and Jack Daniels just to name a few. When getting to their warehouses the barrels are mostly wet and solid. making the loading nice and easy. Not really, it’s hard to double or triple stack a hundred barrels. What I mean by nice and easy is that when a barrel is dry and the stave starting to come loose, the whole barrel looses its structural integrity. At this point as you try to roll them, the rings will be falling off and the barrel will barely stay together. As long as the very top and bottom ring stay you should be good. Even thought loading dried out barrels can be a pain, it’s actually a benefit for us. Why? Well, since we are furniture makers the wood being dry is a must. If they are not then we have several months to go before our tools can even touch them.

When we receive a New Batch of Whiskey Barrels that aren’t dry enough we have to store them outdoors for a few months. Luckily our location is in Las Vegas where it’s a very dry climate. Even if the summer heat isn’t baking them, the winter alone is a very dry time. Sure the few occasional rain storms pass through but even so the lack of moisture in the air stays minimal all year around. As the barrels dry the rings slip off and they start to lean to onside. Gaps between the staves open up and when you can see sun light through them it mean they are ready to be used. This doesn’t mean we break down barrels as we need them for projects. Every month or so I like to break them down and store all the staves and barrel heads neatly on pallets. This way when it’s time to prep material I already have them ready in an orderly fashion.

I will write another blog where I go into detail on the material prep work sometime in the near future. In the meantime if you have any question or comments please feel free to email me. Also, if you are seeking Coupon Codes and would like notification when new products are available please sign yup for our online newsletter.

Have great day!

-Balazs Moldovan

New Batch of Whiskey Barrels